CNC Machining

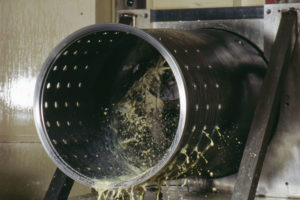

Computer-numerical control (CNC) machining digitizes the controls of machine tooling equipment such as routers, millers, lathes, and shaping machines. Using a CNC machine provides guaranteed precision, efficiency, repeatability, and speed when producing high volume metal parts.Using a 2D or 3D CAD drawing, engineering creates a program which the CNC machine interprets to create the specific part. Once the program is in place, the machine can replicate the process quickly and efficiently to meet the demands of full production runs.

Our CNC machining processes allow the skilled staff at Aero Manufacturing to provide a broad range of metal fabrication processes, including:

- Milling

- Drilling

- Vertical Turning

- Boring and Counter-boring Processes (Contour Turning, Form Turning, Taper Turning, Straight Turning)

- Internal/External Threading Processes

- Tapping

- Internal Forming

- Countersinking

- Pocketing

- Profiling

- Reaming

- Spline

- Parting/Cutting

- Facing

Other specifications of our CNC milling equipment include three-axis and five-axis machining centers, and multiple fixturing options, such as three-jaw and four-jaw chucks, pallets, and in-house fixturing and tooling.

Materials and Volume

Aero Manufacturing’s CNC Machining capabilities utilize a wide range of starting materials, such as:

- Alloy Steels

- Aluminum

- Carbon Steel

- Cobalt

- Iron

- Nickel

- Stainless Steel

- Inconel

- Superalloy Metals

Aero’s skilled CNC operators can handle any production run regardless of size. Whether you need a prototype or low volume run, or a high-volume production run or blanket order, Aero’s experienced staff is prepared to meet the demands of your CNC Machining requirements.

Experience You Can Trust

Starting as a small machine shop in Beverly, Massachusetts in 1971, Aero Manufacturing has grown into one of the most respected fabrication and machining companies on the East Coast. Our 70,000-square-foot state-of-the-art manufacturing facility employs more than 70 highly skilled professionals with an average of 10 years of service with our company. The dedicated staff at Aero strives to deliver a quality product from prototype to production.

We are AS and ISO certified, which means our processes and operations meet the rigorous requirements of the National Quality Assurance Board to ensure quality processes and unparalleled production capability.

A combination of expertise and cutting-edge technology allows Aero Manufacturing to meet even the most rigorous industry standards, such as:

- ANSI

- AS

- ASME

- ASTM

- AWS

- ISO

- Mil-Spec

- NADCAP

- RoHS

- SAE

We are capable of servicing custom projects of any size, and our skilled staff ensures – big or small – that our clients are always 100% satisfied. In fact, Aero Manufacturing provides metal fabrication processes to a broad range of industries including:

- Aerospace

- Commercial

- Defense

- Energy

- Manufacturing

- Medical Devices

- Military

- Power Generation

The experienced engineers and CNC operators at Aero Manufacturing are ready to provide the highest levels of integrity and quality possible. We know each job and customer are unique. In order to provide the necessary attention to detail you require, our staff quotes each job individually.

You can count on Aero Manufacturing for the shortest lead times, highest level of accuracy, and unparalleled integrity for your custom CNC machining needs. Contact us today for more information about our CNC Machining capabilities and how we can ensure your next fabrication project is built accurately and efficiently. Talk to the professional staff at Aero Manufacturing to start your custom quote today.

Machinery List

Dahlih 2100

4-axis with probe

Dahlih 1450

4-axis with probe

Seiki BM 1600

4-axis with probe

Hyundai F960B

4+1 axis

Dahlih MCH 630

4-axis

Hyundai WIA 80G

4-axis

Mori-Seiki SL-4

Mori-Seiki SL-75

Mori-Seiki SL-65

Dahlih 1700

4-axis

Dahlih 1500

4-axis with probe

Hyundai F750B

4-axis with probe

Haas UMC 750

5-axis

Hyundai WIA 63G

4-axis

Okuma Dual Turret LU45

Hyundai L600A

Hyundai L700A

Vertical Turret Lathe 72″ Capacity