Welding Services

Aero Manufacturing provides welding services that adhere to the highest industry standards. With an average of 25 years of experience, the skilled welders at Aero Manufacturing turn welding into an art form. Using more than a dozen metal working methods and more than 150 machine tools in our state-of-the-art facility, our welders perform multi-positional welding at X-ray quality.Our Welding Capabilities

Our welders’ broad range of experience and know-how means Aero Manufacturing can provide a wide variety of seam and spot-welding processes to meet the needs of each individual job.

- Gas Metal Arc Welding (known as MIG welding) forms an arc between a metal electrode and the workpiece, melting the electrode to form a weld bead.

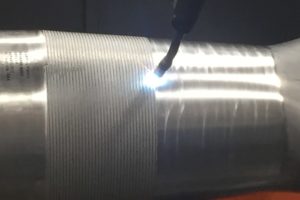

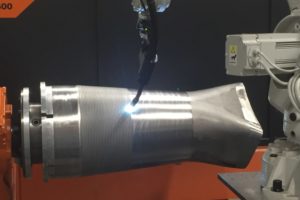

- Cold Metal Transfer Technology (known as CMT) uses a GMAW power supply and robotic arm to introduce a precision additive/cladding process.

- Gas Tungsten Arc Welding (known as TIG welding) is a cleaner method of welding for precision or where the job requires attractive aesthetics.

- Resistance Spot and Seam Welding is widely used for joining sheets and components, and is performed using electrical current to heat the metals and forge them together.

Operations, Materials, and Volume

Through a combination of experienced staff and cutting-edge technology, Aero Manufacturing works with our clients to provide both free hand and robotic cold metal transfer technology welding operations. These processes can be performed on a range of materials, such as:

- Hastelloy

- Stainless steel, stainless steel 300 series and 400 series

- Alloys: aluminum, carbon steel, precipitation hardened nickel, N-263, RENE 41, INCO X750, INCO 718

- Nickel and nickel-based materials: HA230 and HA 282

- Cobalt-based alloys: HS-188, L-605

Aero Manufacturing can handle any production run regardless of size, so whether you need a prototype, low volume run, or you’re ready to begin high-volume runs and blanket orders, Aero’s experienced staff is ready to meet your requirements.

An Industry Leader

As a privately-held company located in Beverly, Massachusetts Aero Manufacturing has specialized in fabrication and machining processes since 1971. Today, we are one of the most respected manufacturing corporations in the Northeast. Our staff of over 70 specialists takes pride in our commitment to 100% accuracy to meet the most stringent customer standards.

Being AS and ISO certified means our processes and operations meet the rigorous requirements of the National Quality Assurance Board.

We can handle production runs of any size. Our skilled staff ensures, big or small, our clients are 100% satisfied. As such, Aero Manufacturing can provide the highest quality metal fabrication processes to a broad range of industries, including:

- Aerospace

- Commercial

- Defense

- Energy

- Manufacturing

- Medical Devices

- Military

- Power Generation

Additionally, we meet a wide variety of industry standards, such as:

- ANSI

- AS

- ASME

- ASTM

- AWS

- ISO

- Mil-Spec

- NADCAP

- RoHS

- SAE

The skilled welders at Aero Manufacturing are ready to bring the highest levels of integrity and quality possible to your welding project. In order to provide the necessary attention to detail you require, our staff quotes each job individually. We utilize the latest in cutting edge technology and tools, so you can count on Aero Manufacturing for the fastest lead times, the highest level of accuracy, and unparalleled integrity for your custom fabrication needs.

Contact us today for more information about our welding services or any of our metal fabrication operations to learn how our staff will ensure your next project is accurate, efficient, and effective. Talk to the professional staff at Aero Manufacturing to start a custom quote today.

Machinery List

Jet Line 9500 Auto Seam TIG Welder

Jet Line LWS-60Z MIG TIG Seam Welder

Robotic ABB / Fronius Flex Arc R with rotary table

Adaptive NC Controlled Spot Welder

Jet Line 9100 Auto Seam TIG Welder

Miller Maxstar 350 TIG Runner

Resistance Spot Welders

Resistance Seam Welders